Shrink Wrap Shinny Sfs Scented Satin PP Polypropylene Blend Perforated Pillow Case Science and Technology Fabric

TC is terylene cotton, terylene cotton fabric is blended fabric of polyester and cotton.The composition of polyester is more than 60%, the composition of cotton is under 40%.

We coalesce into a strong corporate execution force, so that the company faces market risks with a steady hand and achieves to stand out in the Rayon Spandex Knitted Jersey Sports fabric, Rayon Spandex Printed Jersey, STRIPE FABRIC FOR GARMENT industry. Our company actively adopts the modern enterprise management mode, strictly controls every link in production, constantly improves the function and performance of products, constantly improves the quality of employees, and constantly expands and improves the sales network and service network. We closely focus on the development strategy of building a first-class enterprise and establishing a market-oriented operation and discipline mechanism.

POLYESTER COTTON BURN OUT JERSEY

| FABRIC DETAILS: | POLYESTER COTTON BURN OUT JERSEY 32ST/C 125GSM 173CM |

FIBRE CONTENT: | 70%COTTON 30%POLYESTER |

WEIGHT: | 125G, 32ST/C |

WIDTH: | 173CM |

COLOR FASTNESS: | 3~4 GRADE |

MOQ: | 250 KG/COLOR ,500KG/ORDER |

DELIVERY: | Production release: 25 working days |

DEVELOPMENT: | 7-10 working days |

DESCRIPTION

TC is terylene cotton, terylene cotton fabric is blended fabric of polyester and cotton.The composition of polyester is more than 60%, the composition of cotton is under 40%. For this fabric, the composition is 65% Polyester 35% Cotton.

The advantages of TC:

Not only highlight the style of polyester,but also reveal the superiority of cotton. Under dry and wet both condition, elasticity,abrasion resistance and dimension stability are better, shrinkage is small. Further more, quick drying, easy to wash, not easy to fold.

The shortcomings of TC:

Polyester fiber belongs to the hydrophobic fiber, which have the characteristics of easy adsorpt oil, easy produce electricity and adsorpt dust. Terylene cotton is synthetic fiber and cannot be degraded.

Burn-out fabrics are made by blending two different fibers, one of which can be destroyed by a certain chemical agent, while the other is not affected, forming a special style of burn-out prints with a translucent look and a concave and convex pattern.Burn-out printing is mostly used for polyester/cotton fabrics.

TAG

POLYESTER COTTON BURN OUT JERSEY,BLEND KNITTED FABRIC,WEFT KNITTED FABRIC;BURN OUT FASHION FABRIC,TC BURN OUT FABRIC .

Application

It is available for T-shirt、sport shirt、sportwear、leisure etc.

OUR FACTORY

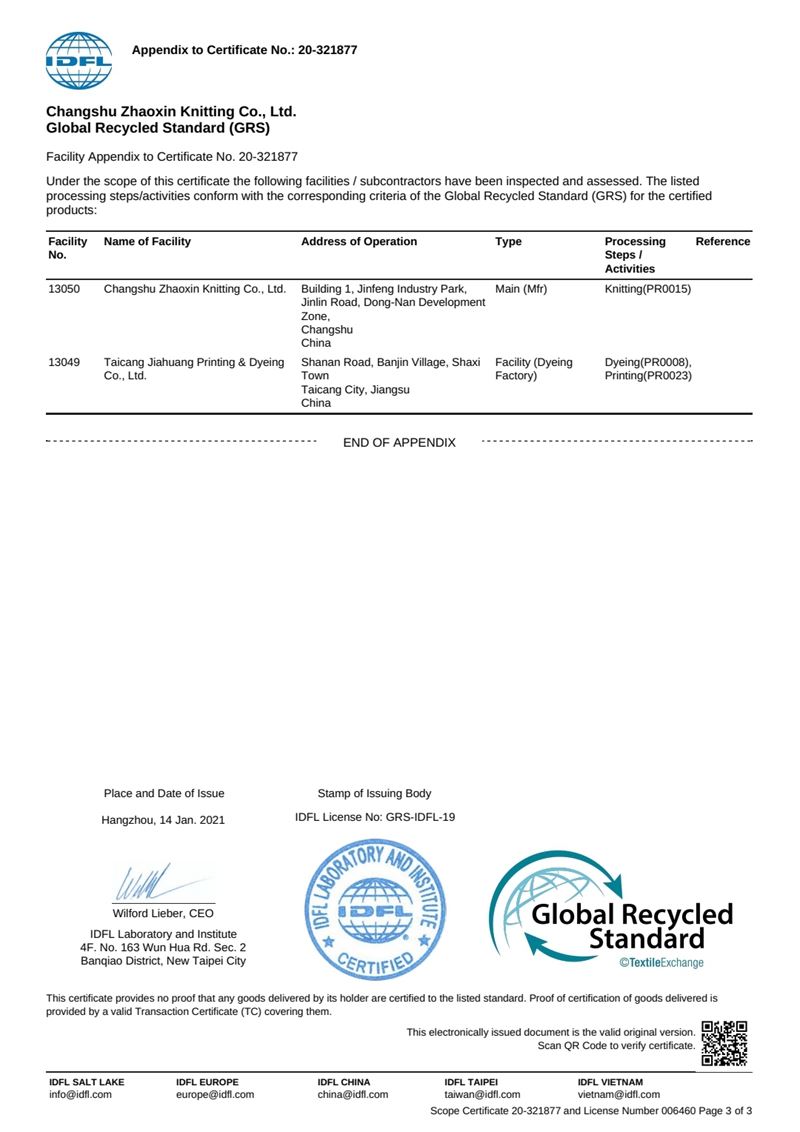

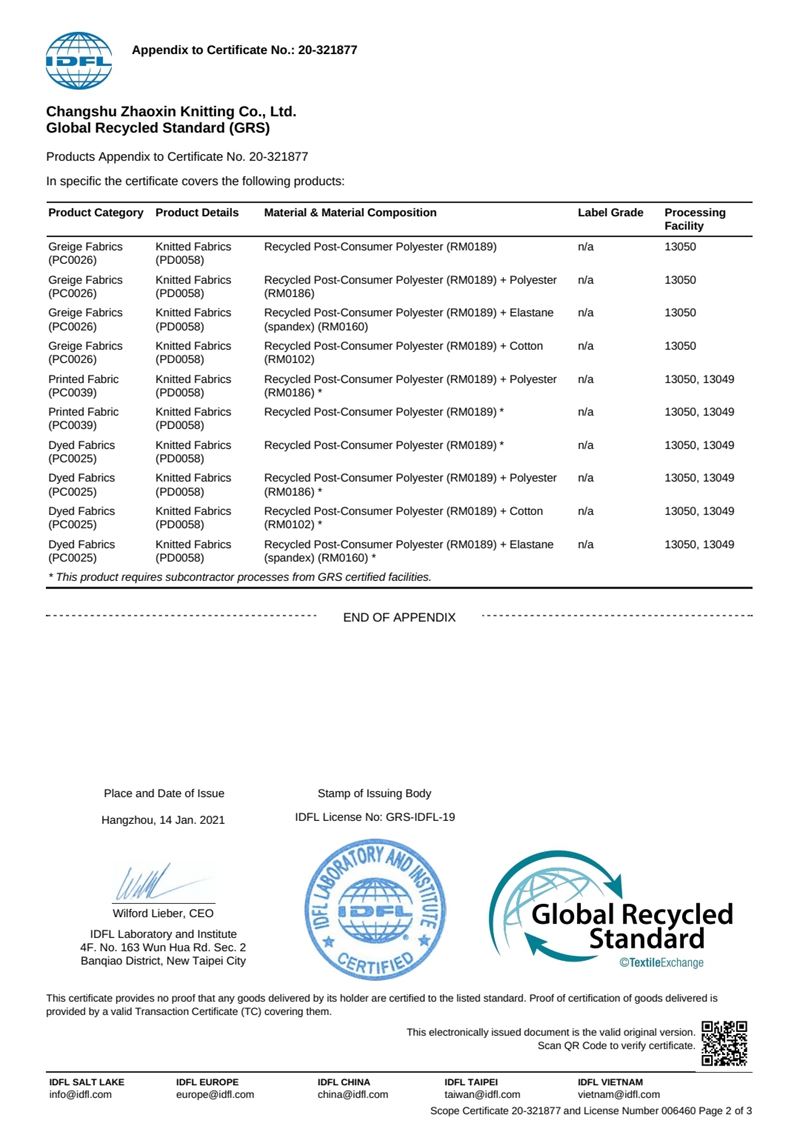

CERTIFICATE

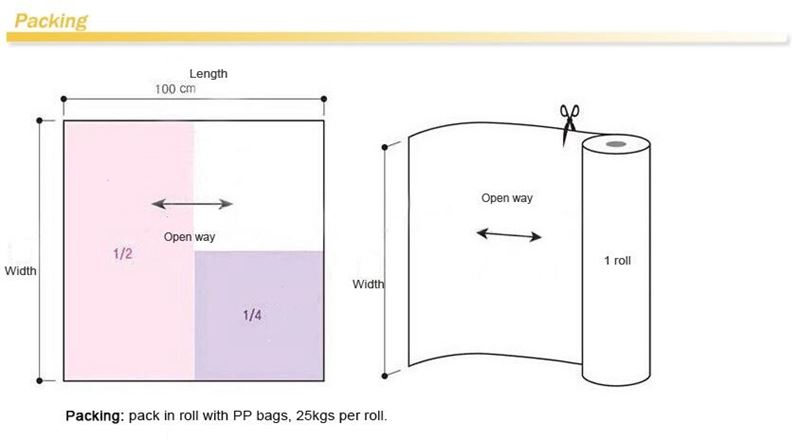

PACKING

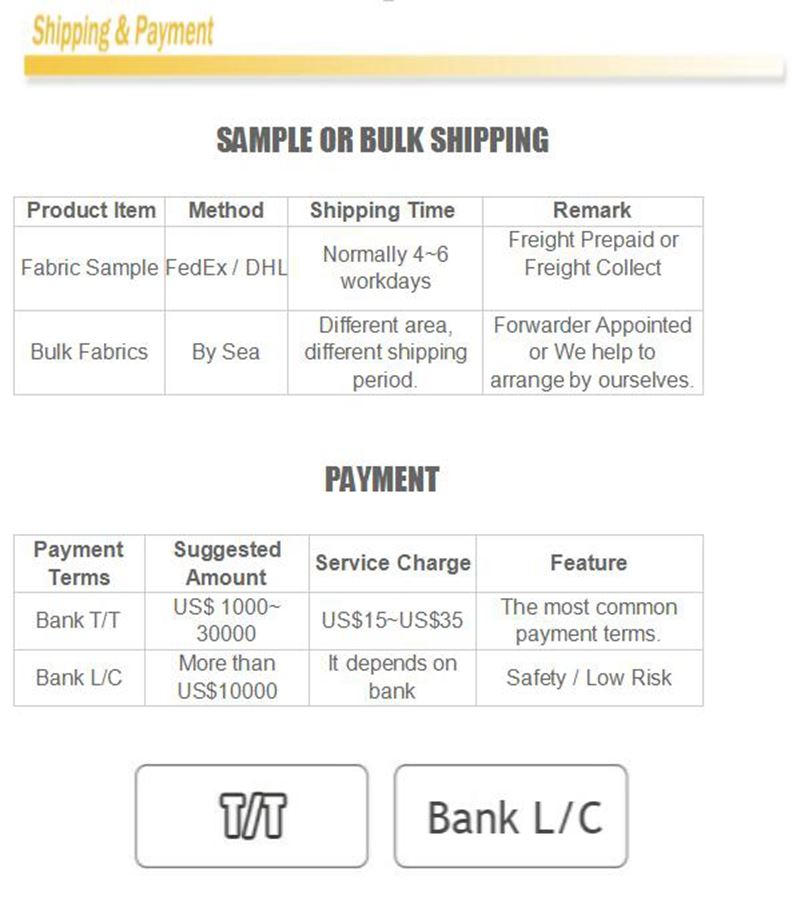

SHIPPING & PAYMENT

After years of development, our company has formed a perfect new product process system, which can quickly develop new products and improve Shrink Wrap Shinny Sfs Scented Satin PP Polypropylene Blend Perforated Pillow Case Science and Technology Fabric. We have an experienced management team and have a place in the industry. The concept of safety is a concentrated expression of the concept, attitude, and code of conduct that an enterprise views and handles safety issues.